Engine Coolant Flow Measurement

When the engine is warm visually watch the coolant in the cooling system to see if it is circulating.

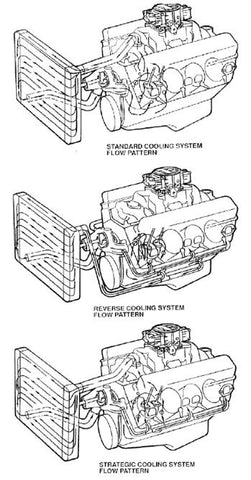

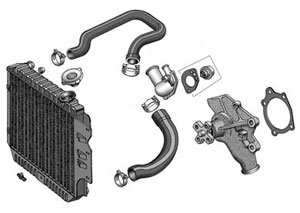

Engine coolant flow measurement. The heat rejection errors can range from 3 to 20 kw and become unacceptably large for precise design. The flow through each orifice in the head gasket can be determined by measuring the pressure drop across each orifice while coolant is being forced through the engine. Unscrew and remove the pressure cap from the cooling system and keep it aside. Most v type engines use cylinder heads that are interchangeable side to side but not all engines.

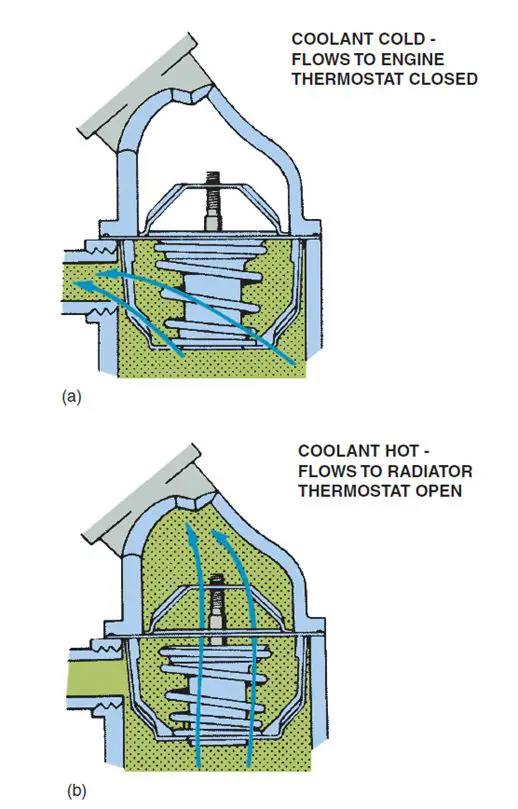

Experimental errors in coolant flow rate and temperature cause variations in the measurement of engine coolant heat rejection. Park your vehicle and allow the engine to cool. Check if the coolant is circulating. The thermostat provides control for your engine s warm up period.

By providing a flow restrictor between upstream and downstream ports a differential pressure is created between the upstream and downstream ports. Coolant flow and head gasket design. Remove the cooling system pressure cap. Low profile inline flow meters with steel or polymer bodies led lighting and straight or 180 degree flow paths.

Approximate read range is 2 0 15 lpm 32 240 gph. Koolance s inline flow meters provide electronic indication of real time coolant flow rate. With an operating flow range of 0 500l min and a compact body flowsonic hf is ideal for in vehicle and lab based coolant circulation measurement. The measured magnitude of this differential pressure allows a microprocessor or similarly configured component to determine.

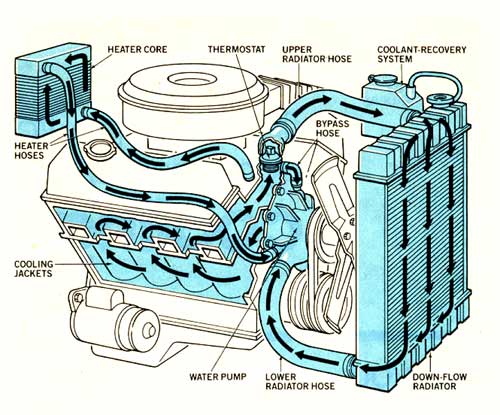

Gill sensors controls design and manufacture level position condition and flow sensors for demanding and critical environments as well as engine controls. Therefore based on the design of the cooling system and flow through the engine it is very important to double check that the cylinder head is matched to the block and that the head gasket is installed correctly end for end so that all of the cooling. A flow meter frequency adapter can be used to convert flow meter values to signals similar to fan rpm tachometry. Coolant flow radiator and engine block below is an explanation of this system s operation the thermostat just like your body needs to warm up when you begin to exercise your car s engine needs to warm up when it starts its exercise.

Coolant flow has a direct relationship to area and an exponential relationship to pressure. In order to measure the engine cylinder coolant heat rejection directly experimental errors need to be minimized. Flowsonic hf is designed to measure high volume flows of coolant and lubricant in all vehicle types. We supply products worldwide to heavy industry defence motorsport and off highway amongst many other markets that demand robust accurate control and measurement in extreme operating conditions.

This model also integrates a thermistor coolant temperature sensor.