Epdm O Rings Uk

These compounds also withstand the effect of brake fluids and skydrol and other phosphate ester based hydraulic fluids.

Epdm o rings uk. 900 series o rings feature a round cross section. Epdm offers outstanding resistance to weather heat and ozone. Epdm o rings are available in any colour shore hardness and size. Trp polymer solutions can supply o rings in epdm nitrile and many other polymeric materials.

With our massive stocks of o rings in nitrile viton and ptfe you can be assured of quick delivery when you need it. Epdm is particularly useful when sealing in brake systems that use fluids having a glycol dot 3 and 4 or silicone base dot 5. Choose from our selection of epdm rubber o rings including over 750 products in a wide range of styles and sizes. Buna n and viton o rings can be used for sealing valves faucets flanges engines and more.

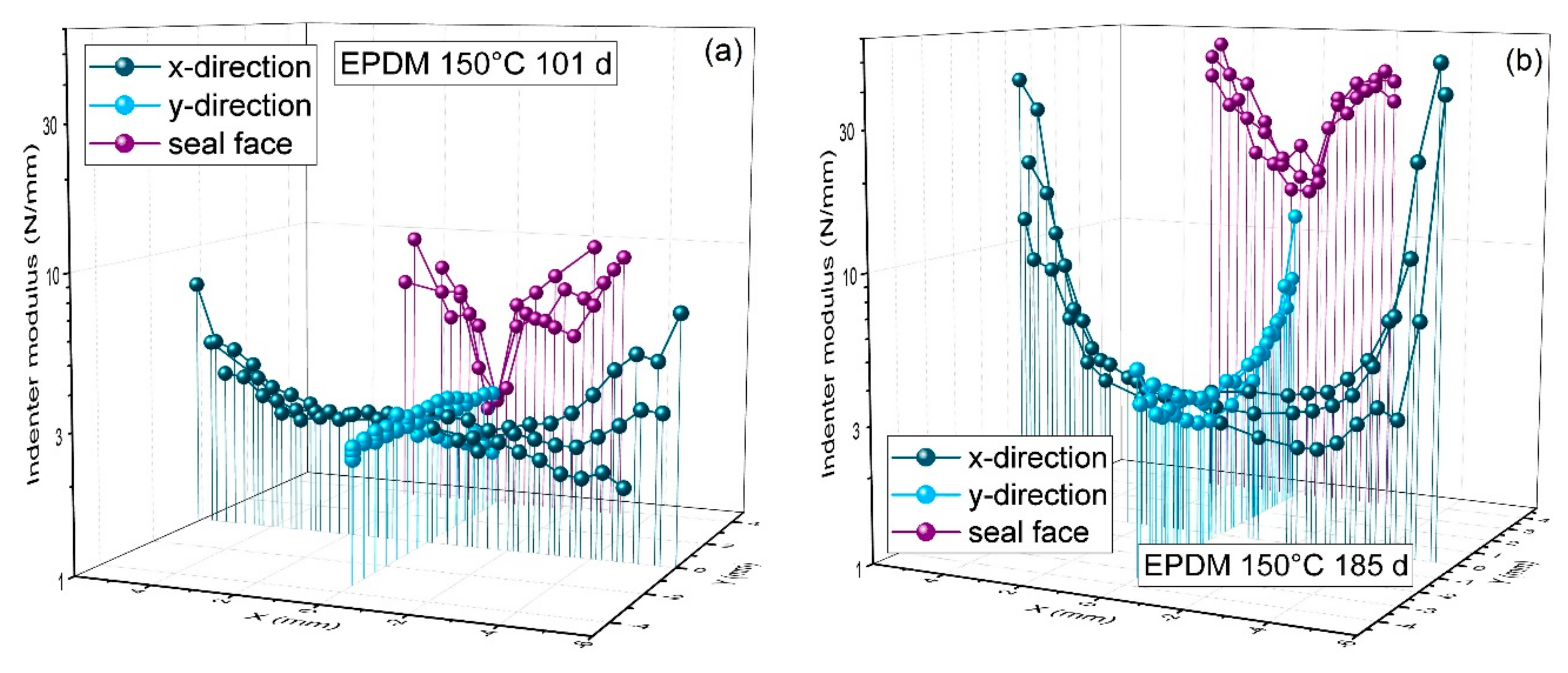

General purpose epdm o rings are manufactured using a sulphur based curing system these are suitable for use up to 120 c whereas peroxide cured o rings can be used up to 150 c. About epdm ethylene propylene diene monomer. Epdm has a great acceptance in the sealing world because of its excellent resistance to heat water and steam alkali mild acidic and oxygenated solvents ozone and sunlight uv. With over 50 million o rings and back up rings in stock we supply to over 5000 customers worldwide.

Each features a round cross section. Epdm o rings click on a size range above to buy online we can also supply epdm peroxide cured o rings. Epdm o ring materials are used in a wide range of water and irrigation applications. For advice and guidance about our various o ring materials or to discuss your application requirements in more detail call trp polymer solutions today on 44 0 1432 268899 or email sales trp co uk.

We also offer epdm seals that are suitable for use with drinking water food applications. Please get in touch and let us know your requirements. In stock and ready to ship. M barnwell services stock an extensive variety of epdm o rings available in many sizes imperial and metric and shore hardness.

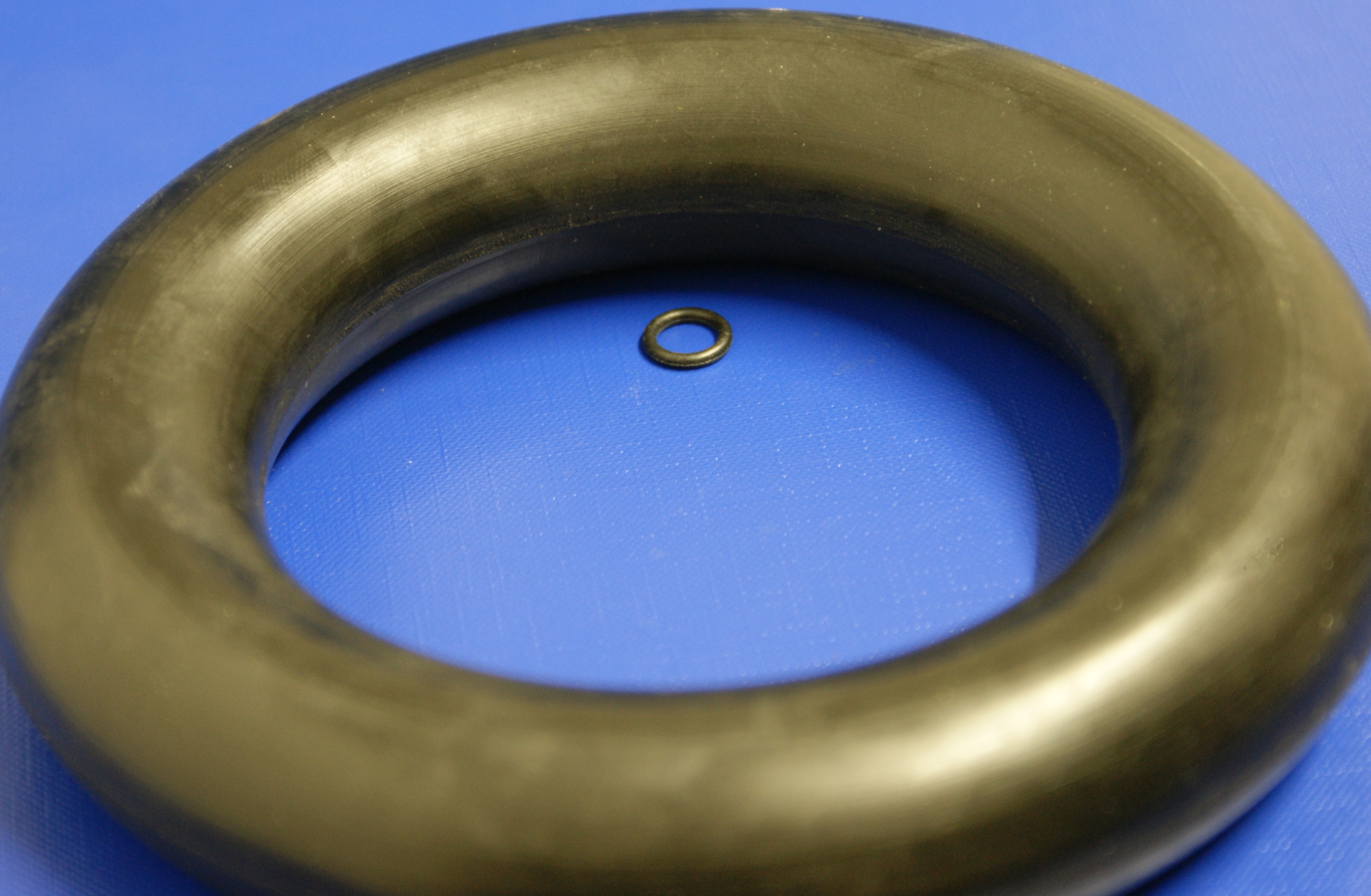

Epdm o rings are not recommended for exposure to most oils. The o ring is a simple versatile economical but essential component with a vast range of uses.