Epoxy Pipe Coating Failures

The result could be a catastrophic high volume pipe failure requiring a high insurance payout which would not otherwise be attributed to epoxy coating.

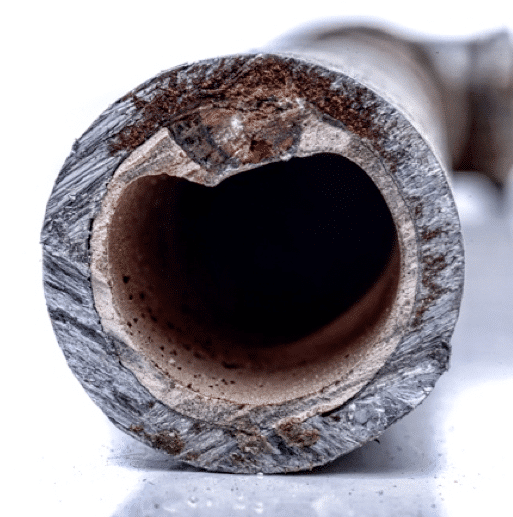

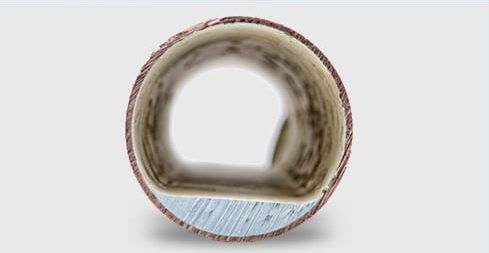

Epoxy pipe coating failures. As such a poorly applied epoxy liner could weaken a pipe considerably. To explore the facts about pipe lining this site organizes the discussion into two sections that correspond to the two primary technologies currently available in the marketplace for typical multifamily properties. When you hear a traditional plumber complain that an epoxy pipe coating does not coat evenly he s probably worked behind a pipe lining company that did not adhere to the proper setup or installation procedures for installing the coating. Most common issues are tree roots in main sewer lines cracks and breaks and or deteriorating or leaky pipes due to age.

Epoxy pipe lining and cured in place pipe cipp within each section the authors provide an overview of the technology. Epoxy coating of steel is a widespread practice in construction and mainline water service 2 3 4. The epoxy pipe lining company will plot the footage and location of damage to determine a plan for. Coatings that have good elongation.

Failed epoxy lining requiring a full repipe of the epoxy lined system within a multifamily property. Corrosion protection subsoil exposure. Polypropylene coatings epoxy primer is used for3 layer systems. The epoxy specialists will perform a pipeline camera inspection to determine what is causing problems in the drain line.

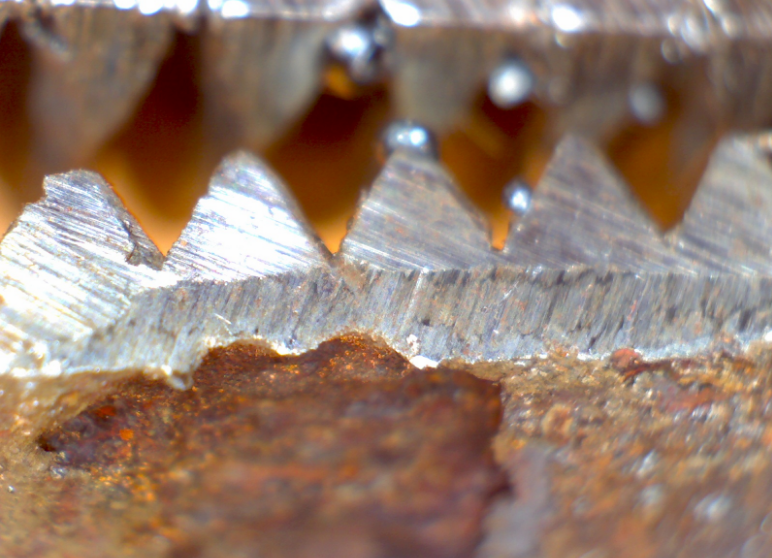

Fusion bonded epoxy coating also known as fusion bond epoxy powder coating and commonly referred to as fbe coating is an epoxy based powder coating that is widely used to protect various sizes of steel pipes used in pipeline construction concrete reinforcing rebars and on a wide variety of piping connections valves etc. Since epoxy coatings only seal and smooth the inside surface of the pipe the host pipe must still be structurally. Once a coating cracks even a tiny micro fracture it is the beginning of failure for the coating. A buried pipeline coating has exceeded its useful life when adequate cp can no longer be economically maintained.

Epoxies traditionally have elongations of only 2 3 percent. Epoxy pipe lining is often viewed as an alternative to replacing the old piping with a completely new system. Some products like the wet surface epoxies mentioned above are reinforced these fibers act like rip stop nylon or rebar in concrete. Of the coating has been required to maintain adequate cathodic protection werner 3 defines failure as follows.

Epoxy and cured in place pipe. Subsoil exposure coatings designed to protect the pipe surface from its external environment.