Function Of Forced Draft Fan In Boiler

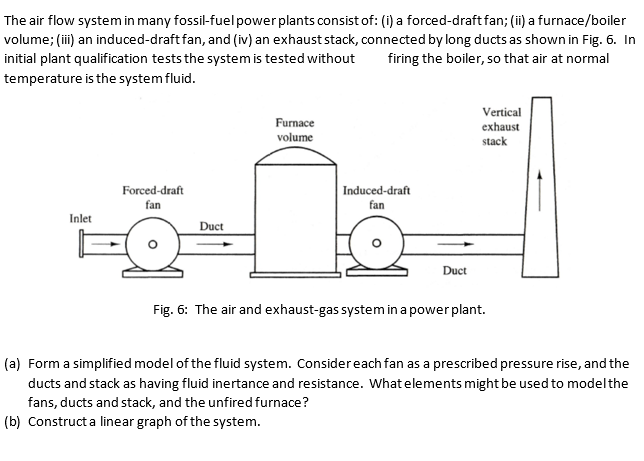

When air or flue gases are maintained above atmospheric pressure.

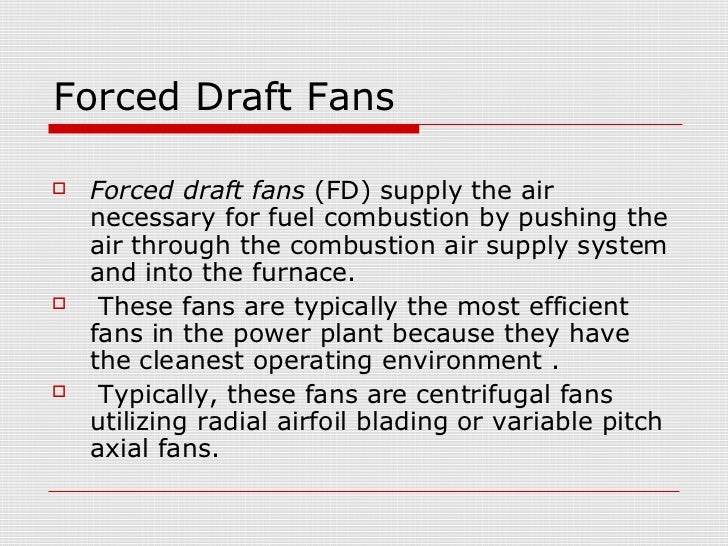

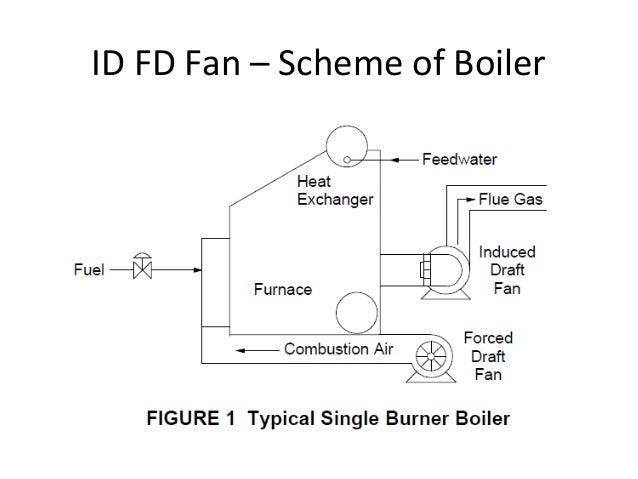

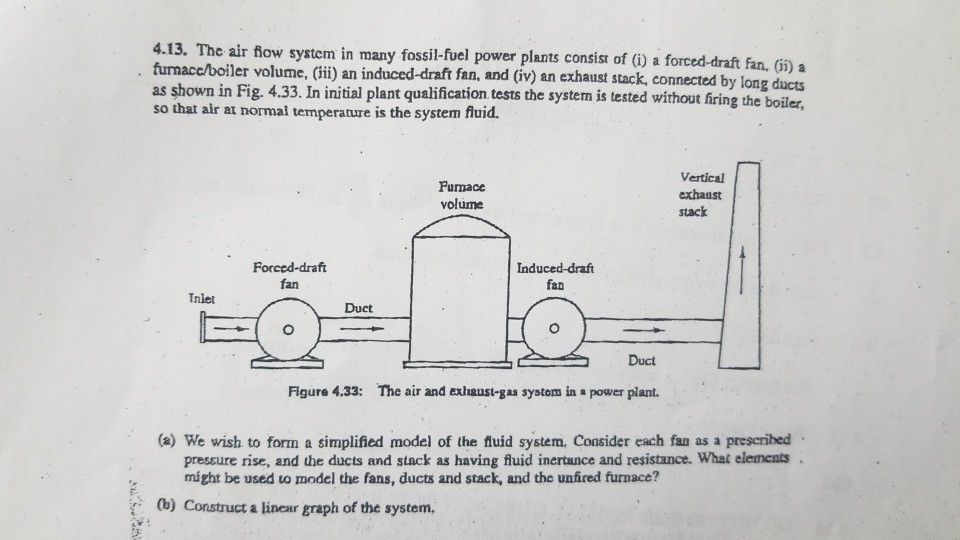

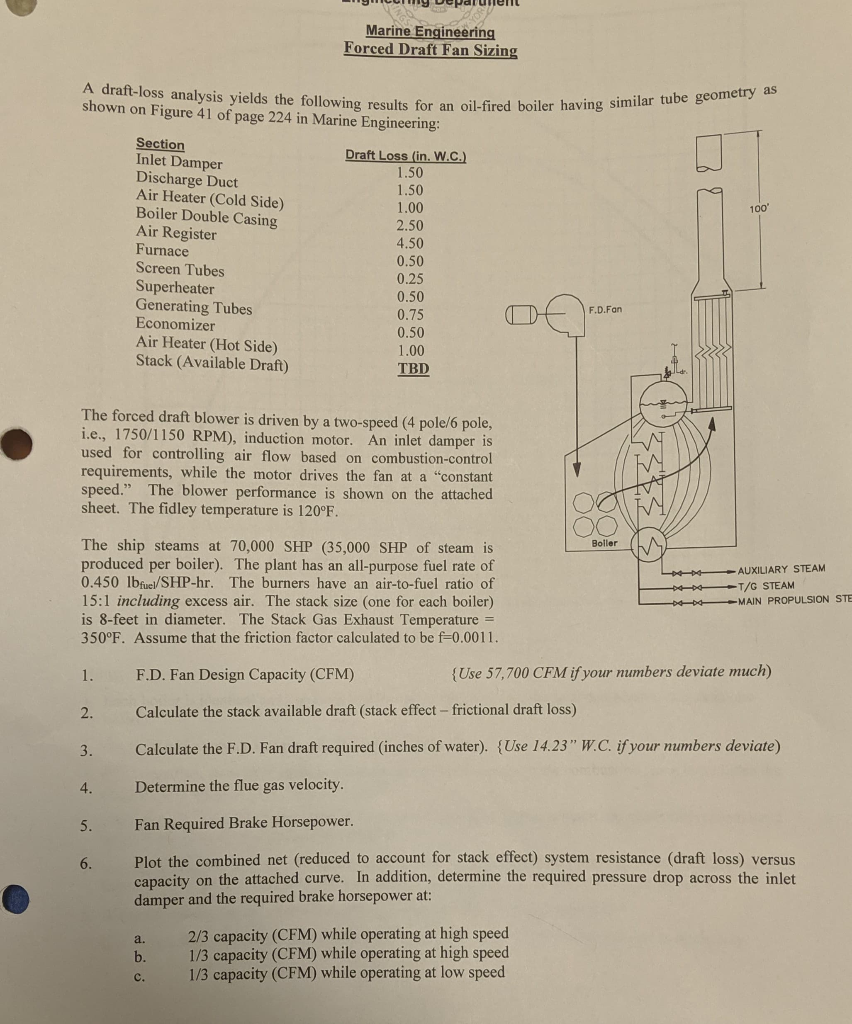

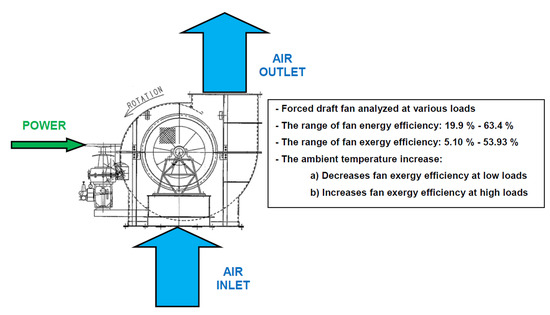

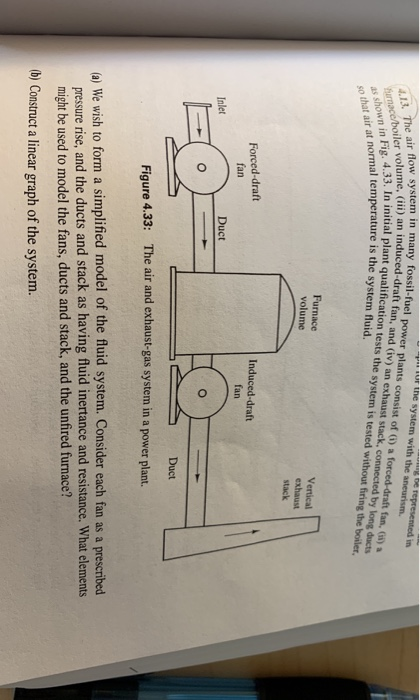

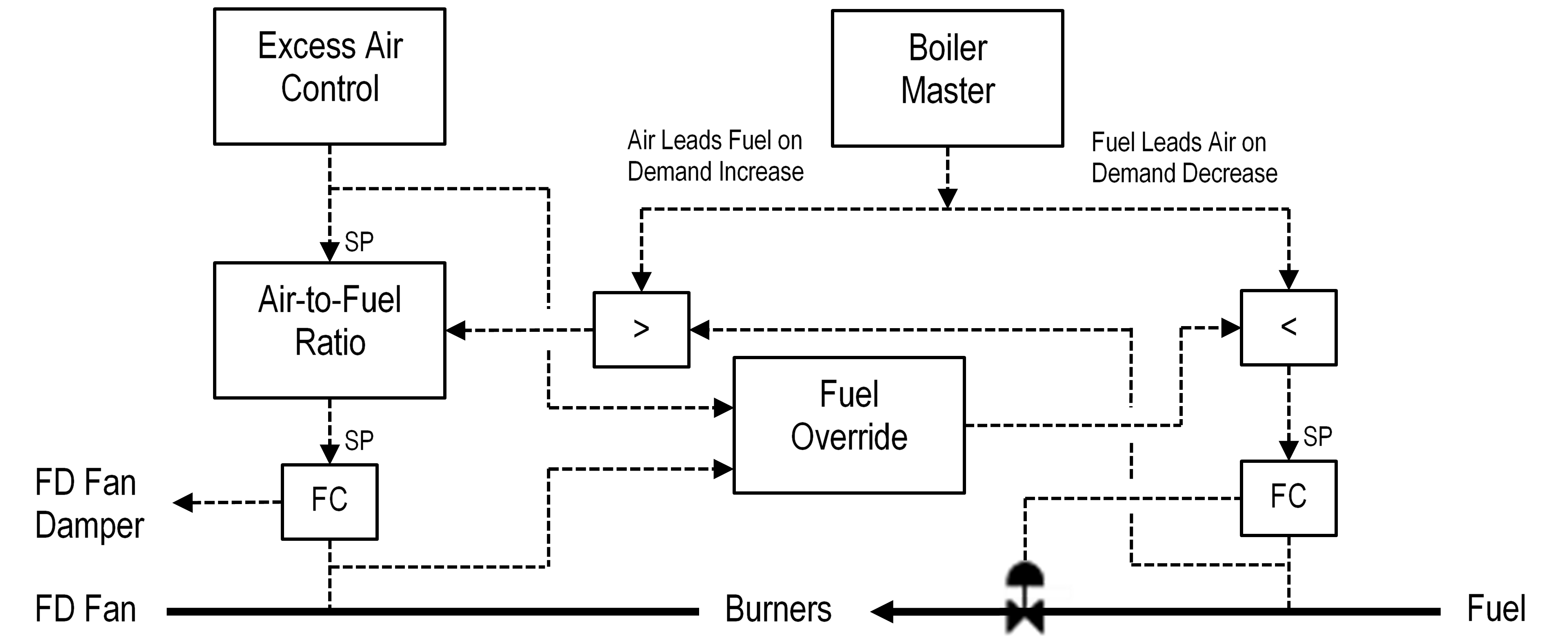

Function of forced draft fan in boiler. The primary difference between a forced draft and induced draft is fd fan forces outside air into the heating system whereas id fan draws flue gases from the system out into the atmosphere. Forced draft fan fd fan in boilers. Forced draft fd a fan is used to force air into the boiler to provide more air for combustion. In this case the system is said to operate under induced draft.

Id fan is basically mentioned here for induced draft fan and id fan is always located between dust collector and chimney. When air or flue gases flow under the effect of a gradually decreasing pressure below atmospheric pressure. This is called fd fan. Forced draft fan is a type of a fan supplying pressurized air to a system.

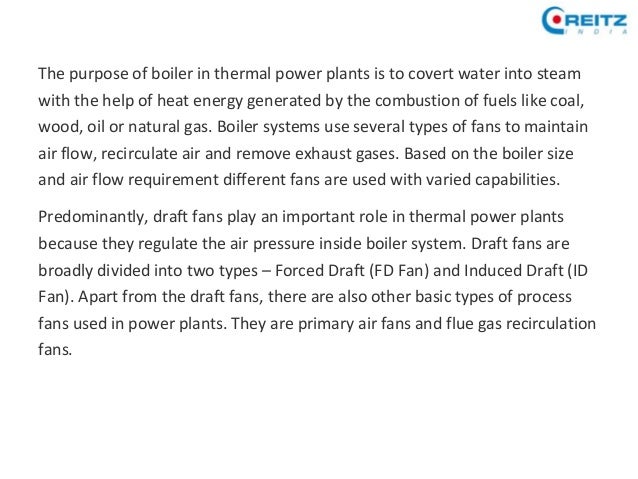

As we know for a steam boiler to generate steam combustion must occur be it any fuel wood coal rice husk pet coke ldo furnace oil and for combustion to exist one of its three main requirements is the air. And this requirement is compensated by a forced draft fan. Induced draft fan is also used to identify the combustion process used in large boilers. Forced draft fan is used basically for providing the required quantity of hot air to the furnace for smooth and uniform combustion of fuel.

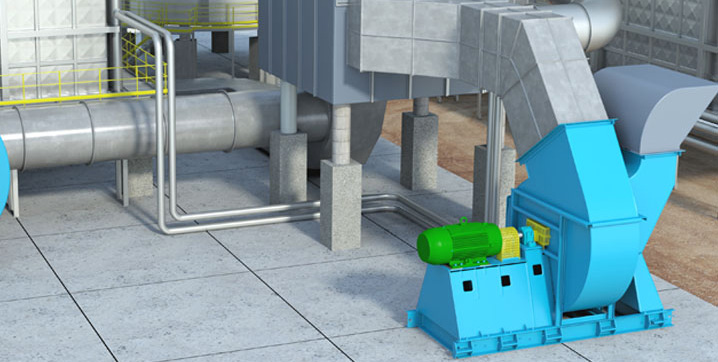

The forced draft fan fd fan is a fundamental part of most boiler systems and is the element responsible for creating draft inside of the boiler. Induced draft fan or id fan is used to create a vacuum or negative pressure in a system like steam boiler or thermal oil heater. Id fan will take the hot flue gases from furnace via dust collector dust separation system or fume extraction system and wi. We are engaged in manufacturing exporting and supplying wide array of forced draft fans.

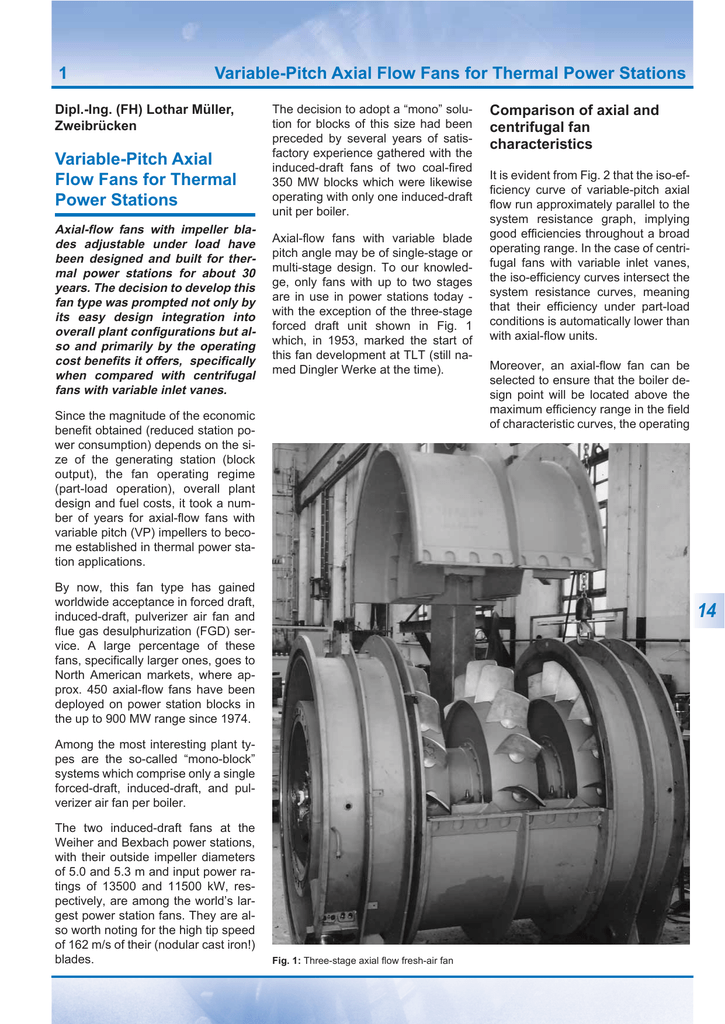

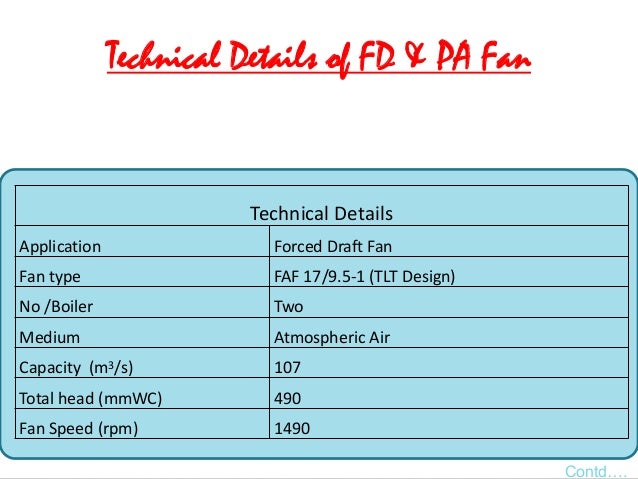

Offered centrifugal type fans are fabricated for a minimum discharge capacity of 20 higher than the theoretical air required at 30 excess air at mcr and head 20 higher than required. Draught fans are a type of industrial process fans and are broadly divided into two types forced draft fd fan and induced draft id fan. A fd fan moves cooler air into the combustion zone while the id fan removes the products of combustion from that zone. When mechanical ventilation is supplied to these boilers the heat transfer rate increases.

In the case of a steam boiler assembly this fan is of great importance as we know for a steam boiler to generate steam.